|

Model DCSS Straight Side Press

|

|

| |

|

|

|

Self contained hydraulic system with oil cooler and

filter Self contained hydraulic system with oil cooler and

filter

|

|

Machine tool quality direct hydraulic

cylinder Machine tool quality direct hydraulic

cylinder |

| |

|

|

Full length EIGHT way ram guides Full length EIGHT way ram guides

|

Box type ram Box type ram |

| |

|

|

Solid end frames to provide the most rigid design of any

press Solid end frames to provide the most rigid design of any

press

|

Adjustable shaft packing Adjustable shaft packing |

| |

Tonnage Control Completely adjustable open height,

stroke and speed change point Tonnage Control Completely adjustable open height,

stroke and speed change point |

|

T-slots in the bed and ram T-slots in the bed and ram

|

| |

|

Windows for material and die pass

through Windows for material and die pass

through

|

|

Two hand control station Two hand control station

|

|

Extremely heavy duty welded frames Extremely heavy duty welded frames

|

| |

|

|

A counterbalance valve for punching and a decompression

system for bottoming applications are standard

equipment A counterbalance valve for punching and a decompression

system for bottoming applications are standard

equipment

|

**For Punching Or Blanking applications De-Rate The Overall

Press Tonnage By 1/3 |

| |

|

|

| |

Loading Applications for

the

Model DCSS Straight Side Press |

|

|

|

|

|

|

Typical window for model DCSS, shown with air tank for die

cushion and an automatic lubrication system

|

|

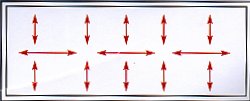

Center/Off-Center/Front to Back and/or Left to Right

loading |

Model DCSS500 |

| |

|

|

|

|

Built similarly to the DC style press, the DCSS takes yet

another step toward providing the most frame strength available on

any press on the market. The DCSS has enclosed end

frames in lieu of the gap therefore allowing the least amount of

deflection and the most rigidity. The operator can

still however have material or die pass through with windows

located in the end frames.

Built with the same hydraulic system and solid welded

construction as the DC, the DCSS gives you another layer of

strength for even the most punishing applications.

Typically the bed and ram would stay within the frames, but

optionally you can order the DCSS with ram and/or bed extensions

to extend beyond the frames to give you even more die

area.

The DCSS is also available up to 600 tons and is perfect

for center load and off center loads left to right and/or front to

back as well as virtually any other press application.

|

|

|

|

|

Model AM Straight Side

Press

|

|

| |

|

|

|

|

The model AM straight side press is a more

traditional style of straight side with much more left to right

bed and ram area. The AM is able to hold

tolerance left to right much better than a direct hydraulic design

due to its bellcrank linkage that gives the press full tonnage

from one end of the press to the other. This single cylinder

design develops full tonnage anywhere along the bed left to right

and front to back. The bellcrank linkage system is

actuated with a single cylinder utilizing A660 bronze at

the bearing points. |

|

|

Model AM200-10 |

|

200

ton press in automated feed line & optional paint

|

| |

|

|

| These bearings are

Designed to withstand up to 6 times the machines overall tonnage

and they are covered by our extensive 5 year parts warranty.

The model AM is truly designed to accept virtually all

forms of press applications whether it is punching, forming,

blanking, coining, swedging, die tryout, trimming, drawing and so

on. The AM is available up to 600 tons and particularly excels at

progressive die set ups where you have varying amounts of tonnage

being applied across the bed all in the same stroke.

**For Punching Or Blanking applications De-Rate The Overall

Press Tonnage By 1/3 |

|

|

| |

Massive unitized welded frame Massive unitized welded frame |

| |

Extremely simple low pressure hydraulic system with

cooler Extremely simple low pressure hydraulic system with

cooler |

| |

Ram mounted controls and/or pedestal controls are

available Ram mounted controls and/or pedestal controls are

available |

| |

Enclosed end frames w/windows for pass thru of material,

dies, feeding equipment, etc Enclosed end frames w/windows for pass thru of material,

dies, feeding equipment, etc |

| |

| |

|

|

400 ton straight side press with optional light curtains,

extra t-slots in the bed and ram, automatic lubrication system and

air counterbalance system with air tank and optional white

paint |

|

| |

|

| |

|

|

| |

Loading Applications For the Model AM Straight Side

Press |

|

Single cylinder bellcrank linkage system

generates full tonnage all across the bed and ram

|

|

|

| |

Center/Off-Center/Left to Right and or Front to Back

Loading |

Model AM500-10

500 ton capacity x

10' |