|

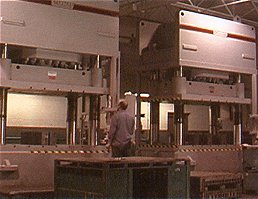

Model AP1000 (1,000 ton) shown with optional rubber pad

enclosure mounted under ram. All other features shown are

standard equipment . Model AP1000 (1,000 ton) shown with optional rubber pad

enclosure mounted under ram. All other features shown are

standard equipment .

|

|

| |

|

|

|

Model AP300 (300 ton capacity) |

|

Model AP1000

with optional color (1,000 ton capacity) |

|

Loading

Applications for

the model AP

Four Column Press

|

|

Center Loading

or

|

Even tonnage

across bed

|

| |

|

|

|

|

Standard Industrial

model AP Four column presses are manufactured for a variety of

applications in metalworking and other fields.

Four column presses are best utilized for center load

applications and/or for evenly distributed tonnage applications

like embossing and rubber pad forming

Off center loading applications can be done on four column

presses, but they will require optional load balancing devices

like stroke dampers or nitrogen cylinders.

Available from 100 to 1,000 tons the model AP four column

press is available with a wide variety of options that will make

it one of the most versatile presses on your floor.

|

Two AP300 Presses

|

|

|

| |

|

| |

|

| |

|

| |

|

|

|

|

Applications For Model AP:

Embossing

Drawing

Stamping

Die Try-out

Sizing

Rubber

Pad Forming

Forming

Swedging

Trimming

Punching (*)

Blanking (* )

|

|

|

|

Model AP w/ optional

bolster/die rollout

arms and

rubber pad holder

and paint color |

All model AP presses are available w/ longer open height

and stroke. |

| |

|

|

|

|

(*)

Punching/Blanking

Due to the overall

weight of the ram and weight of the ram and punching or blanking

with a four column press, you should limit your overall tonnage to

50% unless stroke dampers are used

|

|

|

| |

AP300 press with optional

light curtains and interlocking

side barriers & with special

low bed height |

Model AP600 press with

optional die bolster rollout arms; light curtain safety systems

and air actuated quick change die system located in t-slots rubber

pad box and paint color

|

| |

| |

|

|

The model AP Four

column press is a vertical, down acting direct hydraulic

press with a guided platen powered by an extremely heavy duty

machine tool quality hydraulic cylinder. The precision

machined platen is fitted with bearings made of A660 bronze and

rides on machined platen is fitted with bearings made of A660

bronze and rides on The massive structure is fabricated from heavy

sections of prime steel plate. This press is designed for

heavy production work for all sizes of facilities. The self

contained hydraulic system uses a hi-low circuit using directional

valves for speed control. As with all Standard Industrial

machines, the model AP comes with our unmatched 5 year warranty,

plus T-slots in the bed and ram, a decompression system, overload

protection and many more impressive standard features.

|

|

Two Twin AP1000 presses with optional color

|

| |

|

| |

|

| |

|

|

|